Industrial and Hydraulic Hoses, Service Loops, Hydraulic Power Units, Specialized Offshore Equipment Manufacturing

PEM Offshore is an Exclusive Distributor of DELAFIELD CORPORATION, USA. DELAFIELD Manufactures Hydraulic Power Units, Hydraulic & Electrical Service Loops, Hydraulic & Pneumatic Valve Actuation, Hoses (Flexible Metallic, Hydraulic, CNG, and Including API Std 1529 Aviation Fueling Hoses) and other related Manufactured Products for the Oil, Petrochemical and Natural Gas Industries.

Delafield carries such recognized brands as: Parker Hannifin, Goodyear, Dixon, Evertite, Alemite, American Boa, Penflex, Omegaflex, Snaptite, Anchor Fluid, Inline Valves, Noshok, Titan Industries, Weg Motors, Deltrol & Atlas Cylinders. Delafield Corporation is certified to the following Quality specifications: API Q1, ISO/TS 29001, ISO 9001:2008, AS9100 Rev. C and PED (Pressure Equipment Directive).

Hydraulic Power Units (HPU)

Delafield has the capabilities to design and manufacture Hydraulic Power Units to meet the exacting requirements of most industries. The Delafield team will work with your technical staff to deliver a product that exceeds your expectations for quality and cost efficiency. Delafield has manufactured HPU’S with oil capacities of 50 to 700 gallons, 50 and 60 Hz motors, flow rates of 15 to 200 gpm, and pressure to 5000 psi. All HPU’s can be supplied with UL listed CSA listed or ATEX certified components, and fully wired and tested.

You can select from one of Delafield’s standard Hydraulic Power Units or we can design a custom unit with the following features:

- 25 hp (19 kW) to 400 hp (300 kW)

- Single or Multiple Pump Configurations

- Flows from 15 gpm (57 lpm) to 300 gpm (1135 lpm)

- Pressures up 5000 psi ( 345 bar)

- 50 or 60 Hz, 380 through 690 VAC

- Stainless Steel tanks and corrosion resistant frames

- With or without Starters and control Circuits

- UL or ATEX components for hazardous areas

- Immersion heaters

- Duplex filtration, and ease of maintenance designs

- Reduced noise levels

- Full factory functional testing

Please consult our engineering department for the Electrical Service Loop that meets your application.

Service Loops: Electrical

Delafield Corporation has been manufacturing Service Loops for various Top Drive manufacturers for over 15 years. With the knowledge that we have acquired from these years we have developed and patented (US and foreign patents pending) an improved service loop design. This patented design is the only major improvement in service loop technology since the fist loops were built in 1982. Our new loop design allows for the securing of each loop to prevent excessive movement and damage due to wind and motion; increasing the life of the loops.

This restraint system combined with full length urethane potting and twisted cables (rope lay) results in Loops with higher densities and reduced lateral motion. Less unnecessary motion means loops last longer and can be installed in more demanding conditions.

Delafield can manufacture Electrical loops with all sizes of power conductors from 444 to 1111 MCM. Lengths from 50 foot to 200 foot, and diameters from 2 inch to 6 inch ID can be manufactured.

We currently manufacture Electrical Service Loops for several manufacturers and drilling contractors.

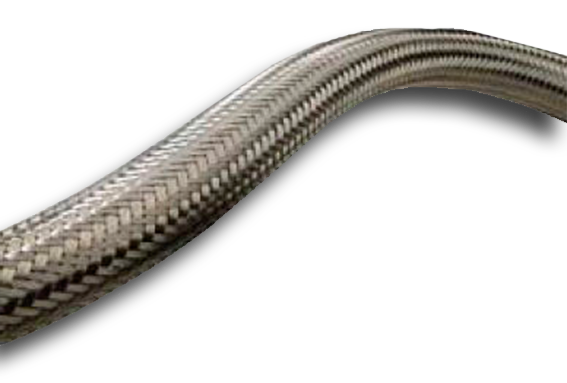

Delafield is one of the largest Corrugated Metal Hose fabricators west of the Mississippi. We are a hose distributor for nationally recognized brands such as OmegaFlex®, American Boa, Penflex, Hose Master, and Able Metal Hose.

- Cryogenic Metal Hose Assemblies – Temperatures down to -450°F

- High Temperature – High Temperatures up to 1500°F

- Chlorine Hose – Built & Fabricated to (Spec: Chlorine Pamphlet 6, Latest Revision)

- Caustic Chemicals Hose

- Seismic Applications

- Power Generation – Turbines, Solar Fields, Alternative Fuels, Green Technologies

- Exhaust – High Velocity Bleed Duct

- Vacuum – Autoclave (Including Interlock)

- Petroleum Drop Hose

- Materials – 304, 316, 321, Bronze, and Monel®

- Unbraided, Single Braid, Double Braid, Triple Braid Available

- Pressures up to 5,000 PSI – Vacuums down to 29 inches of Hg

- Hose construction conforms to ASME B31.1, ASME B31.3, Boiler and Pressure Vessel Code (B&PV)

- Flexible metal hose assemblies certified to European Pressure Equipment Directive (PED)

- Welders qualified to ASME Section IX & AWS

- JIC, SAE, NPT, Face Seal (Seal-Lok®), Metric, Tube End, Instrumentation, Code-61, Code-62, ANSI Flange & Pipe Fittings

- Internal Flow Liners, External Armor Guard, Firesleeving Available

- Pressure Testing up to 10,000 PSI – Helium Leak Testing down to 1×10-9 TORR

- Full Manufacturer Warranty

Visit www.dftcorp.com for details